Water Quality

Water Quality

In late 2019 and early 2020, we invested in our water quality management process by installing a state-of-the-art WaterTectonics water treatment system at our Mark West Quarry.

We invested in this system to enhance our stormwater management abilities, to exceed what is required to comply with new stormwater regulations, and to maintain our longstanding commitment to environmental innovation and stewardship at all BoDean facilities.

In addition to implementing this new system at our Mark West Quarry, we put in a similar WaterTectonics system at our Santa Rosa Asphalt Plant facility in September of 2021.

We work hard to maintain our shared water resources, and work closely with water experts and regulatory agencies to act as responsible stewards of this essential resource.

Water Conservation

Water Conservation

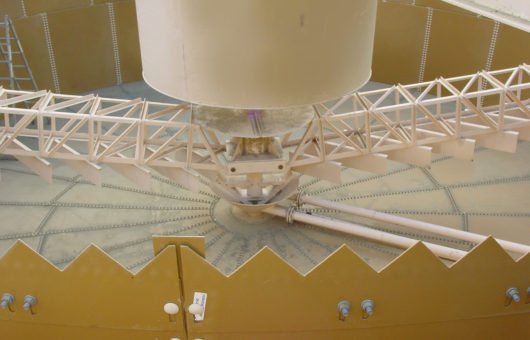

In 2006, we invested in the installation of a self-contained closed loop washing system at our Mark West Quarry. In 2019, we installed the same type of closed loop washing system at our Blue Rock Quarry.

Made up of a Phoenix HiFlo circular thickening plant and overhead beam Diemme recessed-plat-frame filer, these systems capture and reclaim approximately 99% of the water used in the sand production process.

Producing sand locally reduces costs and emissions, saving projects from having to ship or haul sand from out-of-state. Producing sand also requires large amounts of water and energy. Our team invested in these self-contained closed loop washing systems so that we could efficiently and effectively produce sand at both of our rock quarries.

These systems have made it so that we can produce sand for local projects here, in Sonoma County, instead of having to truck sand in from British Columbia or other out-of-state sources. The increased local supply has resulted in reduced emissions and lower costs for local projects.